CDO

Contract Development Services

Contract Development Services

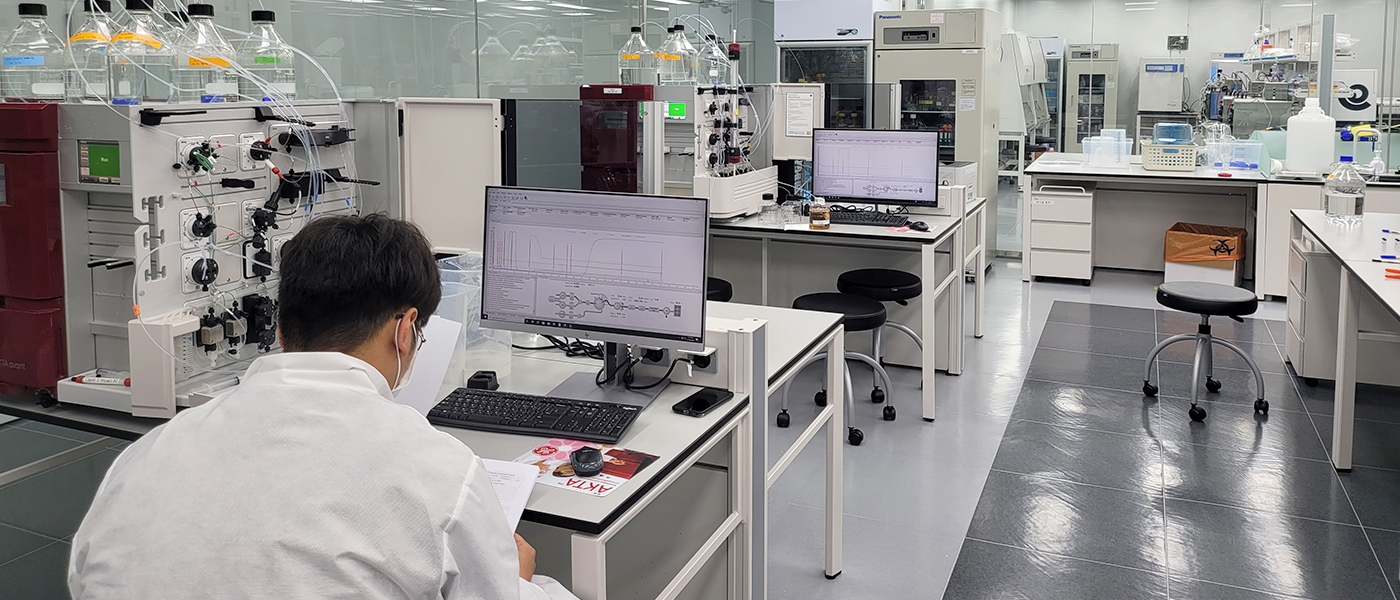

Contract Development service includes initial stage development research such as cell line development, research cell bank / master cell bank development and characterization. We are developing process technology, formulation technology, and various analysis methods for upstream and downstream processes.

1. Cell line development, MCB bank development and characterization

Possible to produce high-productivity cell lines for antibody drugs using our own patented technology on ‘bicistronic expression vectors for antibody expression and methods for producing antibodies using them’.

Screen individual cells to discover the optimal cell line.

Development of stable high expression cell line

We are developing stable, high-expression cell lines that provide high productivity through our own patented technology on ‘bicistronic expression vectors for antibody expression and methods for producing antibodies using them’.

Production of promoters included in both the first expression cassette and the second expression cassette.

Confirmation that the light and heavy chain genes of antibody therapeutics can be highly expressed at the same time along with the amplified gene.

2. USP and DSP development

Optimization of the culture process through a patent on ‘method for producing antibody by adjusting the sugar content of antibodies’.

Development of leading technology that enables antibody purification without using expensive Protein A resin, which is exclusively supplied by several suppliers.

Antibody production method by adjusting the sugar content of the antibody. This technology was the first to confirm that the afucosylation content of an antibody can be increased using glycerol, and the sugar chain content of the antibody is controlled using manganese and uridine. . This allows to consistently produce a high-quality target antibody population. In addition, the cultivation process is simplified and the efficiency is high in terms of time and economy.

2-1. Upstream process development

We are securing an economical and highly productive culture process through the development of a culture process. Design of Experiment (DoE) studies, Media/Feed development and strategy optimization.

A method for preparing an antibody by controlling a sugar content of the antibody

This technology was the first to confirm that glycerol can be used to enhance the afucosylation of an antibody. It uses manganese and uridine to control the sugar chain content of an antibody. This allows you to consistently produce a high-quality target antibody population. In addition, the cultivation process is simplified and the efficiency is high in terms of time and cost.

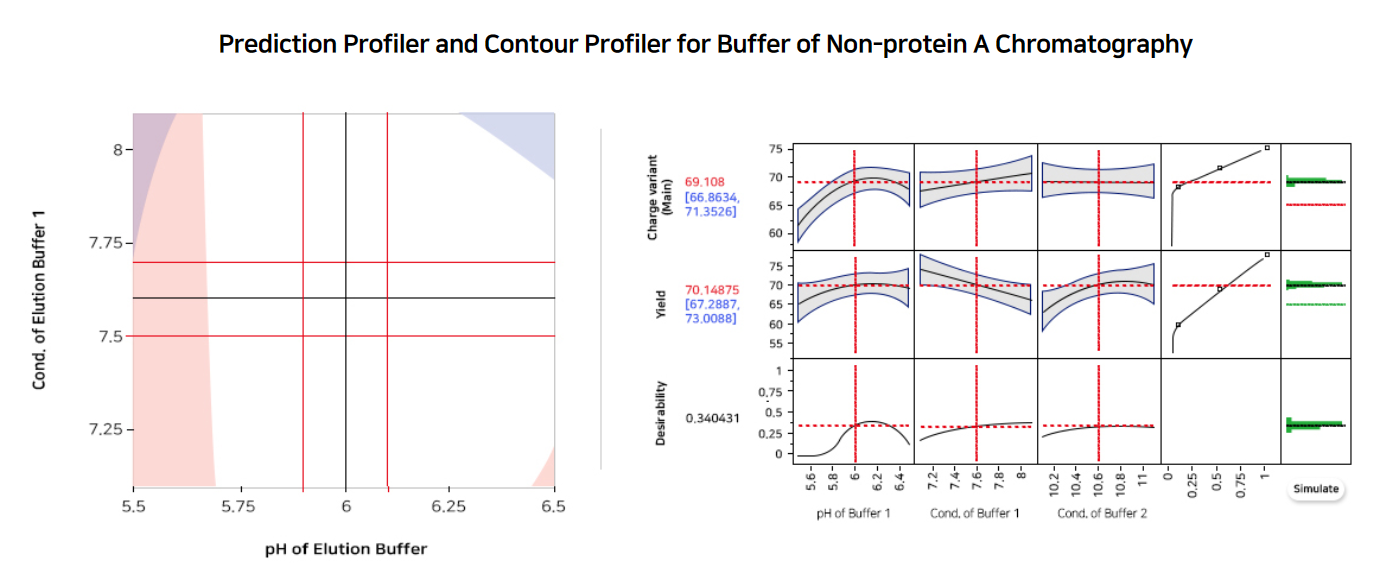

2-2. Downstream process development

Prestige Biologics develops an optimal purification process by utilizing a patented technology, “Antibody Non-Protein A purification process”.

Securing an economical and efficient purification process through the development of a purification process.

Design of Experiment (DoE) studies

Resin screening

UF/DF development

Calculation of In-Process Control & In-Process Testing (IPC & IPT) conditions

Protein A purification process vs Non-Protein A purification process

Detailed purification steps may vary depending on the product.

Chon and Zarbis-Papastoitsis, 2011; Pinto et al., 2015; Xenopulos, 2015)

3. Formulation technology development and analysis method development

Development of patient-friendly drug formulation technology through manufacturing process optimization and drug stabilization technology.

• Product stability and patient-friendly formulation development

• Liquid formulation

• Lyophilization development

• Production process optimization

• Stability

Formulation development

01. Preformulation

02. Development of DS

03. Early-stage formulation development

04. Late-stage formulation development

4. Non-GMP DS & DP production and IND Filing support | CDO

We continuously control R&D and production processes related to DS and DP drug quality, and support systematic management between drug development processes.

Open-door Policy for customer

Prestige Biologics is committed to fostering close collaboration through transparent information sharing in order to provide customer-centric services. We adopt an open-door policy to swiftly address key issues that arise during development and production, and we fulfill the role of a partner to successfully achieve shared goals.

Through our customer service objective of “Growth through Openness,” we believe that we will develop advanced technology and fulfill our mission to contribute to the lives of patients.

From clinical development to commercial production

Prestige Biologics provides various services such as analysis service, clinical development, clinical sample production, clinical secondary packaging (double-blind packaging), process development, and commercial production. We respond flexibly to the needs of customers of various needs, such as CDO, CPO, CMO, and CEO. We are also always open to partnerships that develop potential.